RoadReader Nuclear Density Gauges

he Troxler RRoadReader Nuclear Density Gauges are used by many contractors, engineers and highway departments for compaction control of soil, aggregate, concrete and full asphalt.

Product Code

UTS-1050 RoadReader Nuclear Density Gauges Model 3440P

Standards

ASTM D 2950, C 1040, D 6938

The Troxler RoadReader nuclear moisture / density gauges are used by many contractors, engineers and highway departments for compaction control of soil, aggregate, concrete and full asphalt. The ASTM standarts numbers D 2922, D 3017, D 2950 and C 1040 are met or exceeded by these gauges. Two test models are avaliable for density determination: Direct transmission and Backscatter. The operator selects the mode depending on the material type and thickness of the layer being tested. The model 3430 is avaliable with keypad, display and operator’s manual in languages and is the siplest most economical gauge offered by Troxler. The Model 3440 provides 30 special functions, storage of up to 1000 test records, an 18-month warranty and many more options that make it simple to operate and a necessity for all technicians.

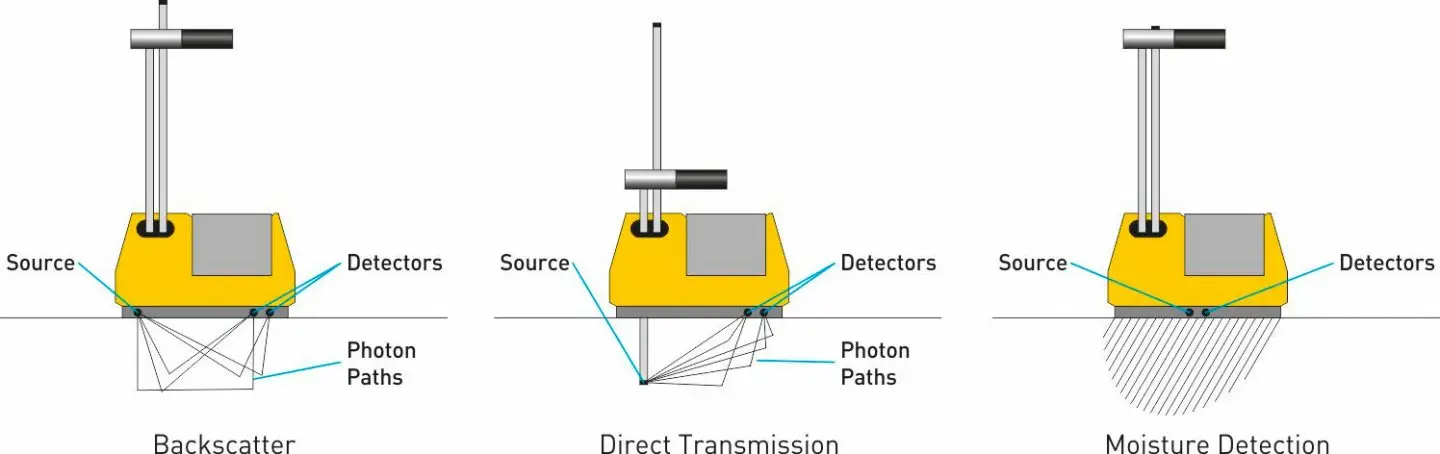

Three Test Modes

BACKSCATTER

Backscatter is rapid and nondestructive. The gamma source and detectors remain inside the gauge which rests on the surface of the test material. Gamma rays enter the test material and those scattered through the material and reaching the detectors are counted. Backscatter is primarily used to determine density on layers of asphalt and concrete approximately 4″ thick.

DIRECT TRANSMISSION

The gamma source is positioned at a specific depth within the test material by insertion into an access hole. Gamma rays are transmitted through the test material to detectors located within the gauge. The average density between the gamma source and the detectors is then determined. Erros resulting from surface roughness and chemical composition of the test material are greatly reduced and aguge accuracy is improved. Direct transmission is used for testing lifts of soil, aggreaget, asphalts and concrete up to 12″ depth.

MOISTURE DETECTION

The moisture measurement is nondestructive with the neutron source and detector located inside the gauge just above the surface of the test material. Fast neutrons enter the test material and are slowed after colliding with the hydrogen atoms present. The helium 3 detector in the gauge counts the number of thermalized (slowed) neutrons which relates directly to the amount of moisture in the sample.

Both Models Offer

- Direct readout of wet density, dry density, moisture, %moisture, %voids and %compaction.

- Lightweight

- Powered by rechargeable nicad batteries or backup alkaline batteries

- Prompts user through steps of operation

- Software allows for moisture, density and trench offsets

3440 Features

- Data storage- stores up to 1000 complete test records which canbe downloaded to a printer or computer.

- Extended storage-gauge allows notes to be stored with test record.

- Automatic indexing-eliminates a major source of operator error by automatically sensing depth of measurement.

- 30 special functions provided-self test and service programs, selected precision and field calibration for special materials.

- Calculator mode with storage.

- Nomograph method for measurement of asphalt overlays.

| Measurement (U.S. Customary Units) | ||||||

|---|---|---|---|---|---|---|

| Direct Transmission Density (6″) Pcf=lb/ft3 | 15 sec. | 1 min. | 4 min. | |||

| Precision at 120 pcf | ±0.42 pcf | ±0.21 pcf | ±0.11 pcf | |||

| Composition error at 120 pcf | ±1.25 pcf | ±1.25 pcf | ±1.25 pcf | |||

| Surface error (0.05″, 100% Void) | -1.1 pcf | -1.1 pcf | -1.1 pcf | |||

| Backscatter (98%) (4″) | 15 sec. | 1 min. | 4 min. | |||

| Precision at 120 pcf | ±1.00 pcf | ±0.50 pcf | ±0.25 pcf | |||

| Composition error at 120 pcf | ±2.50 pcf | ±2.50 pcf | ±2.50 pcf | |||

| Surface error (0.05″, 100% Void) | -4.7 pcf | -4.7 pcf | -4.7 pcf | |||

| Moisture at 15 pcf | 15 sec. | 1 min. | 4 min. | |||

| Precision at 15 pcf | ±0.64 pcf | ±0.32 pcf | ±0.16 pcf | |||

| Surface error (0.05″, 100% Void) Depth of measurement @ 15 pcf (8.45″) | -1.12 pcf | -1.12 pcf | -1.12 pcf | |||

| Measurement (S.I. Units) | ||||||

|---|---|---|---|---|---|---|

| Direct Transmission Density-150mm | 15 sec. | 1 min. | 4 min. | |||

| Precision at 2000 kg/m3 | ±6.8 kg/m3 | ±3.4 kg/m3 | ±1.7 kg/m3 | |||

| Composition error at 2000 kg/m3 | ±20.0 kg/m3 | ±20.0 kg/m3 | ±20.0 kg/m3 | |||

| Surface error (1.25mm, 100% Void) | -17.0 kg/m3 | -17.0 kg/m3 | -17.0 kg/m3 | |||

| Backscatter (98%) (100mm) | 15 sec. | 1 min. | 4 min. | |||

| Precision at 2000 kg/m3 | ±16.0 kg/m3 | ±8.0 kg/m3 | ±4.0 kg/m3 | |||

| Composition error at 2000 kg/m3 | ±40.0 kg/m3 | ±40.0 kg/m3 | ±40.0 kg/m3 | |||

| Surface error (1.25mm, 100% Void) | -75.0 kg/m3 | -75.0 kg/m3 | -75.0 kg/m3 | |||

| Moisture | 15 sec. | 1 min. | 4 min. | |||

| Precision at 250 kg/m3 | ±10.3 kg/m3 | ±5.1 kg/m3 | ±2.6 kg/m3 | |||

| Surface error (1.25mm, 100% Void) Meas. Depth @ 250 kg/m3 – 212.5mm | -18.0 kg/m3 | -18.0 kg/m3 | -18.0 kg/m3 | |||

| Radiological | ||||||

|---|---|---|---|---|---|---|

| Gamma Source | 8 mCi ±10% Cs-137 | |||||

| Neutron Source | 0.060 mCi ±10% Cf-252 or 40 mCi ±10% Am-241:Be | |||||

| Source Housing | Stainless Steel Encapsulation | |||||

| Shielding | Tungsten, lead and cadmium | |||||

| Surface Dose Rates | 19 mrem/hr max., neutron and gamma | |||||

| Source Rod Material | Stainless Steel | |||||

| Shipping Case | DOT 7A, Type A Yellow label II, Tl=0.3 | |||||

| Mechanical | |

|---|---|

| Case | High Impact Plastic 75L x 35W x 42 T in. |

| Vibration Test | 0.1 in. (2.5 mm) @ 12.5 hz |

| Drop Test | 300 mm on 25 mm diameter steel ball |

| Operating Temp: | Ambient: 14 to 158°F (-10 to 70°C) Surface: 350°F (175°C) |

| Storage Temp. | -70 to 185°F (-55 to 85°C) |

| Weight | 29 lbs. (13.2 kg) |

| Shipping Weight | 90 lbs. (40.8 kgs) w/case |

| Available Models | 8″ or 12″ index rod with 1″ or 2″ increments (200 or 300 mm index rod with 25 or 50 mm increments) |

| Electrical | |

|---|---|

| Time Accuracy and Stability | 0.005%, 0.0002% / °C |

| Power Supply Stability | 0.01% / °C |

| Stored Power | 30 watt hours |

| Battery Recharge Time | 14-16 hours (automatic cutoff) |

| Charger | 110/220 V ac, 50-60 Hz or 12-14 V dc |

| Readout | 2 x 16 alpha-numeric liquid crystal display |

| Notes | |

|---|---|

Gauge returns to Gauge Ready (power saving mode) after two minutes of inactivity, except in standard, stat test, drift test, and in nomograph programs when a 30-minute delay is provided. After 5 hours of inactivity, gauge performs complete power shut-down. Battery packs are fully protected against overcharge and overdischarge. Emergency Use – Capable of operation with D size alkaline batteries. |